- Steve Estabrook, Lead Tuner

- MZR DISI

VersaTuner E85 Tuning Guide

Applies To The Following Mazda Vehicles:

- 2006-2007 Mazdaspeed6, Mazda 6 MPS, Mazdaspeed Atenza

- 2007-2013 Mazdaspeed3, Mazda 3 MPS, Mazdaspeed Axela

- 2007-2012 Mazda CX-7

Background

The Mazda MZR DISI 2.3l turbo engine was never released in a flex-fuel configuration. Due to lower cost at the pump and an R+M/2 octane rating of 95-97, there is a great desire to run E85 fuel in high performance turbocharged engines. Unfortunately, E85 fuel has a significantly different ideal air/fuel ratio than gasoline. As a result, you can not run pure E85 fuel without modifying the fuel calculations, air fuel ratio targets and timing in the ECU. This guide will describe how to use VersaTuner to tune your Mazda vehicle for use with E85 fuel.

Warnings

Ethanol (the 'E' in E85) is very harmful to many materials. VersaTune does not guarantee that your vehicle's fuel system is compatible with E85. Use of E85 in your vehicle is done at your own risk. You can read more about ethanol and E85 here

The stock high pressure fuel pump used in Mazda MZR DISI 2.3l turbo engines does not have sufficient flow capability to handle the 30%+ increase in fuel flow required with E85. Do not attempt to run E85 fuel without a high pressure fuel pump upgrade.

This procedure will not make your vehicle into a Flex Fuel vehicle. You must refuel with the same E85 ratio each time or recalculate the correction factor and reflash your ECU when you change the E85 ratio.

Seasonal Blends of E85

To improve cold starting and drivability, E85 is blended differently based on seasonal weather conditions. Summer blend E85 (called Class 1 in the US) contains up to 83% ethanol, whereas winter blend - Class 4 contains as little as 51% ethanol. So, it is important to know the blend of E85 that you have. You can ask the retailer if they know the actual ethanol percentage of the E85 they sell, or if you live in the US, you can refer to the regional E85 volatility class maps which list which class of E85 is sold by month by state:

Page 31 - https://www.afdc.energy.gov/uploads/publication/ethanol_handbook.pdf

You may want to create seasonal tunes to match the E85 blend sold locally.

The Math

As mentioned previously, E85 has a very different ideal air/fuel ratio than gasoline. Here we will explain how to calculate the value to enter into VersaTuner to compensate for this.

The specific gravity (density relative to water) of ethanol is 0.794 (60/65°F).

The specific gravity of pump gasoline is a range from 0.72 to 0.78 (60/65°F) depending on the seasonal hydrocarbon blend and ethanol content (up to 10% E10). Mazda chose to use 0.74 as the specific gravity value for fueling calculations in the ECU.

Our first task is to calculate the actual specific gravity of the fuel we are going to run. We will assume a summer blend containing 83% ethanol and 17% blendstock oxygenate for blending (BOB) aka gasoline.

0.794 * 0.830 = 0.659

0.740 * 0.170 = 0.126

0.659 + 0.126 = 0.785

Based on our calculations, we see that the specific gravity of our 83% ethanol 17% gasoline blend is approximately 0.785. To calculate the specific gravity for a different percentage of ethanol content, simply change the multipliers to reflect the percentages of ethanol and gasoline in your blend.

Next we need to account for the different ideal air fuel ratios of gasoline and E85

Ethanol has an ideal (stoichiometrically correct) air to fuel ratio of 9.0:1.

Pump gasoline has an ideal (stoichiometrically correct) air to fuel ratio of 14.7:1.

Here we will calculate the stoichiometrically correct air to fuel ratio for our blend.

9.00 * 0.83 = 7.47

14.7 * 0.17 = 2.50

7.47 + 2.50 = 9.97

The stoichiometrically correct air to fuel ratio for our blend is 9.97:1

Again, to calculate the stoichiometrically correct air to fuel ratio for a different percentage of ethanol content, simply change the multipliers to reflect the percentages of ethanol and gasoline in your blend.

Here is where it gets tricky. Despite considerable effort, we have not been able to locate the AFR constant used in the ECU for fueling calculations. So, we need to modify the specific gravity constant with a value that combines the adjustments for the specific gravity and stoichiometrically correct air fuel ratio for our fuel blend.

Here is how to combine these adjustments into a single modified specific gravity value that you can put into VersaTuner.

The ECU presumably uses 14.7:1 as the stoichiometrically correct air fuel ratio, however as we calculated above, we need to use 9.97:1

9.97 / 14.7 = 0.678

0.785 * 0.678 = 0.532

To adjust the fuel calculations in your ECU to run an 83/17 blend, simply enter 0.532 into the specific gravity constant in VersaTuner. We are able to modify the final fuel calculation by modifying the specific gravity constant because the specific gravity is one of the values multiplied together by the ECU to calculate the final injection amount. Don't get too stressed out about getting this exact to the ten thousandths place. Your ECU can handle +/- 25% fuel variances with the fuel trims. Do try to get it as close as is reasonably possible though.

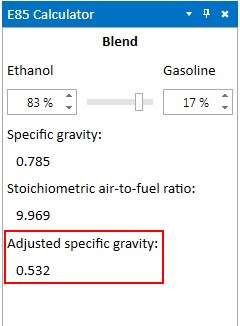

The Math Made Simple

As of VersaTuner 1.9.5, there is an E85 calculator built in to the Tune Editor.

Click on the E85 Calculator button to open the E85 calculator.

The E85 calculator will calculate the value to enter into the fuel specific gravity table to compensate for your specific ethanol/gasoline ratio.

Adjust the ratio to reflect the ethanol/gasoline ratio that you are running. The calculator will output the specific gravity value to use based on the calculations described above.

Tuning Changes

Fuel

The specific gravity change above takes care of the fuel calculations inside the ECU. Next we need to address the tuning changes required when running E85. Ethanol has a different maximum rich AFR than gasoline. The max rich power AFR for pure ethanol is 6.429:1 whereas for gasoline it is 12.5:1. Since the ECU uses lambda for fuel ratios, we will continue the discussion using lambda so that the values obtained can be plugged directly into VersaTuner.

The max rich lambda for ethanol is 0.714. The max rich lambda for gasoline is .850. We will calculate the max rich lambda for our 83/17 fuel blend.

0.714 * 0.830 = 0.593

0.850 * 0.170 = 0.145

0.593 + 0.145 = 0.738

From this calculation we know that our max rich target lambda is 0.738. You will notice that the stock tune on your vehicle has lambda targets as low as 0.6. This is to provide additional charge cooling to prevent knock. Ethanol has nearly triple the latent heat of evaporation compared to gasoline. That means that it cools the intake charge nearly three times better than gasoline. As a result, overly rich mixtures are not needed with E85 to provide effective charge cooling. This is one of the major benefits of E85 in turbocharged engines. It's like having a built-in water/meth spray kit.

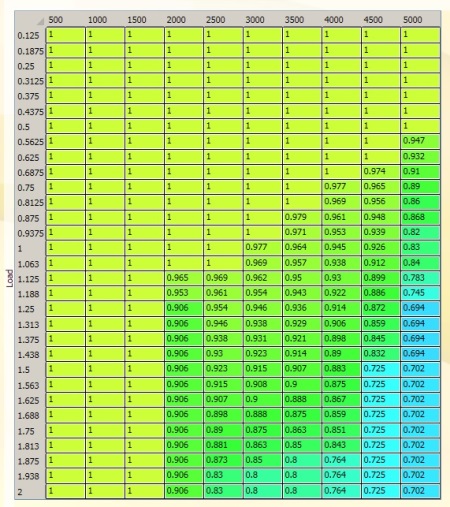

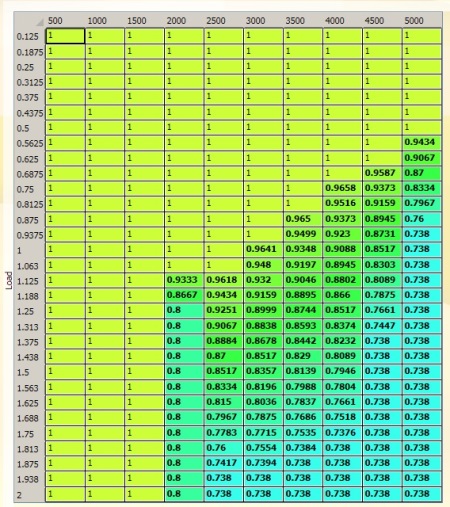

You will need to modify your fueling tables to adjust the lambda targets so that they are no richer than 0.738 (with 83/17 summer blend) unless knock is observed. You will also need to adjust your part throttle / moderate load lambdas for E85 use.

Looking at the stock closed loop fuel table below and left, you can see that 0.907 lambda at 1.625 load and 2500 rpm is too lean for E85. You will need to modify these cells to richen them up or else you will experience knock. Higher loads and RPM will require richer mixtures. You may want to set your higher load cells to the max power rich lambda value and use the linear interpolation tool in VersaTuner to adjust the cells at lower loads. Cells with a stock lambda of 1.000 should be OK as is. The table on the right has been adjusted for an 83/17 blend of E85.

Be sure to adjust all of your fuel tables to contain the appropriate lambdas for your E85 blend.

Cold Starting

Ethanol begins having cold starting issues around 52°F/11°C and it gets worse the colder it gets. E85 having at least 15% gasoline helps, however at colder temperatures, you are starting the engine almost exclusively on gasoline vapors. As a result, a significantly larger injection amount is required during cranking and afterstart until the combustion chamber is sufficiently heated to vaporize the ethanol in the fuel. This is further complicated by the very high latent heat of evaporation of ethanol. In order to get reasonably quick starts and a stable idle after startup, increase the Cold Cranking and Afterstart Enrichment table(s) in VersaTuner. Adjust the slope from -40C to 10C so that there is significantly more fuel at very cold temps and slightly more at warmer temps. Adjust the Cold Cranking and Afterstart Enrichment Decrement table(s) down to increase the duration of afterstart enrichment as needed to keep a stable idle while the engine warms up. This document will be updated with specific values once sufficient cold weather testing has been completed.

Ignition Timing

As mentioned in the Background section, E85 has an R+M/2 octane rating of 95-97. This, combined with the exceptional charge cooling effect, allows for additional ignition timing advance. An increase of 2–7 degrees in timing can be applied. Start by adding 2 degrees and logging knock over all operating conditions. Then increase timing 1 degree at a time while monitoring knock. Low load / RPM cells may not take as much additional timing as high load/ RPM cells. This is because knock at low load / RPM is already very well controlled on direct injection engines.

The result should be a more powerful engine that is less sensitive to knock and heat soak.

Now that you have a tune prepared for E85 use, we'll discuss the process of changing from pump gas to E85.

The E85 Changeover Process

- Verify that your MAF calibration is good.

- Record a datalog of various engine operating conditions and check that the LTFTs and STFTs are acceptable (+/- 10%).

- Correct as needed before proceeding.

- Run your fuel tank to near empty

- Fill the tank with E85

- By emptying the tank of gasoline as much as possible and filling with E85, the E85 is not diluted with the existing gasoline in the tank creating an unknown ratio of ethanol to gasoline. This eliminates the guessing as to what the exact ethanol content is.

- If you are blending gasoline with E85, make sure you calculate the ratio of ethanol and gasoline accurately and take into account the existing fuel in the tank.

- After filling the tank, pull into a nearby parking space.

If you are going from 100% gasoline to 100% E85, don't drive any farther than the parking lot. Running E85 without a proper tune will result in a severe lean condition. - While monitoring the short term fuel trim with the VersaTuner Virtual Dashboard, let the engine idle for about 10 minutes. After a while, you will start to see the STFT rise. Shut the engine off when the short term fuel trim stops rising or reaches 25%.

Your Mazda vehicle is equipped with a returnless fuel pump. This means that the fuel between the in-tank pump and the fuel injectors does not return to the fuel tank. It takes a while to run this gasoline out of the line and get the E85 to the injectors. You will see the STFT slowly increase at first then quickly rise until it hits the max of 25% (less for lower blends of ethanol) - Using VersaTuner, flash your E85 tune to your ECU.

- When you restart your engine, monitor fuel trims with the VersaTuner Virtual Dashboard.

- You should see STFTs similar to what you had while running gasoline.

- STFTs will take a little while to settle down as LTFTs are learned by the ECU.

- STFTs and LTFTs should be +/-10% once LTFTs have had time to learn.

- Operate the engine at idle, then light load while monitoring fuel trims, equivalence ratios, and knock.

- Once you have confirmed that fuel trims are normal, that there is minimal deviation between desired and actual equivalence ratios, and little to no knock, you can operate the engine at full load.

- Continue to monitor fuel trims, equivalence ratios, and knock until you are satisfied that your engine is getting the right amount of fuel.

Please feel free to post any questions or feedback on the VersaTune user forum: https://www.versatune.net/forum